Forklift Maintenance Checklist

To keep your forklift running smoothly, you need to service it regularly, including cleaning, inspections and preventive repairs. With a regular forklift maintenance schedule, your machine can provide years of safe, reliable service. By contrast, neglecting these maintenance tasks will lead to your equipment breaking down more frequently, putting your workers at risk and disrupting operations.

By adopting the maintenance practices in these checklists, you will minimize accidents and extend your investment.

Check the Manufacturer’s Schedule

Did you know the second Tuesday of June is National Forklift Safety Day in the U.S.? The aim is to raise awareness about forklift safety and best practices. More than 40,513 forklift-related incidents occurred in the last reported period. With days away from work, job restrictions and turnover impacted, forklift preventive maintenance is an excellent starting point to promote safety and best practices.

When maintaining your forklift, we recommend you begin by referring to your manufacturer’s forklift maintenance schedule. Keep up with spark plug changes, oil and filter changes and brake checks.

OSHA Regulations and Recommendations

Most warehouses are familiar with several critical forklift preventive maintenance protocols because the Occupational Safety and Health Administration (OSHA) requires them to perform daily inspections.

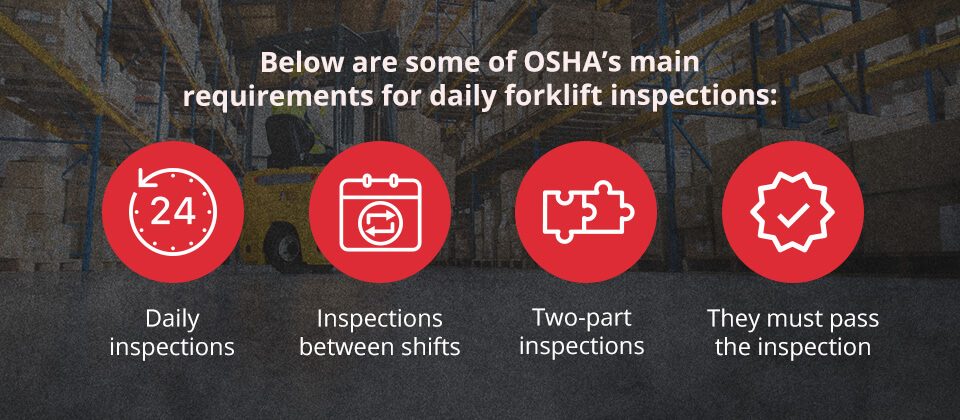

Below are some of OSHA’s main requirements for daily forklift inspections:

- Daily inspections: Forklifts must be inspected at least once per day before they are placed in service.

- Inspections between shifts: Forklifts used round-the-clock must be inspected following each shift.

- Two-part inspections: The operator must first visually check the forklift with the engine off and then conduct an operational inspection with the engine running.

- They must pass the inspection: If the inspections reveal the forklift might not be safe to operate, it must not be operated.

The Importance of Forklift Preventive Maintenance Checklists

Checklists help teams remain organized and stay on top of maintenance tasks. They support standardization, consistency, thoroughness and accountability regarding upkeep, enabling your fleet to perform at its best.

Learn how to maintain a forklift properly with daily, monthly and annual checklists.

Daily Forklift Checklist

While performing the daily inspection of your forklift, make sure of the following. We’ll start with things to check while the engine is off:

- Tires are inflated and free of excessive wear or damage.

- Lug nuts are tight.

- Axles and other moving components are clear.

- Mast and forks show no signs of cracks, wear, bending or rust.

- Mast lift chains and rollers are in working condition.

- Hydraulic lines are free of damage, and fluid levels are good.

- The operator’s manual is on board.

- No visible damage on cables and hoses.

- The data plate is legible and up to date.

- The forklift seat belt, if it has one, is working.

After completing these tasks, turn the engine on and perform the following operational checks:

- The lights, horn and other safety features work properly.

- Lift cylinders are in good condition and free of scars.

- The forklift operates smoothly when moved a distance equaling the length of a truck.

- All brakes, the accelerator and turn signals work well.

- The steering is responsive.

- The forks can be raised up and down fully.

- Cables and hoses are wrapped seamlessly around the guide rails.

- All attachments are undamaged, secure and operational.

- The tilt control operates smoothly without chatter.

- All instruments and gauges work.

[Get Started With Forklift Maintenance]

Monthly Maintenance Items

The best monthly forklift preventive maintenance practices adhere to specific industry standards and closely align with the manufacturer’s recommendations. These practices are more complex and may require specialized diagnostic equipment. For this reason, most warehouses contract their equipment provider to conduct the required maintenance.

Monthly maintenance generally includes a wide variety of tasks that involve every aspect of the machine, including:

1. Lubrication

Lubrication is an essential part of good forklift maintenance and helps ensure that your forklift continues to operate smoothly. These tasks include:

- Lubricating the chassis-mast attachment.

- Changing the engine air filter.

- Cleaning all the breathers.

- Changing the engine oil and filter.

- Checking fluid levels.

- Cleaning and coating the battery terminals.

2. Electrical

Make sure the following electrical components are in working order:

- Switches

- Contact tips

- Drive control system

- Time delay

- All motors, including hoist, drive and steer

- Commutator

- Blowout

- Brushes

- Battery connectors

- Springs

3. Hydraulic

When checking your forklift’s hydraulic system, you will need to examine the following thoroughly:

- Cylinders

- Pumps

- Valves

- All hoses, tubes and fittings

4. Gas

Gas-related components that need inspection during monthly maintenance include:

- Radiator.

- Belts.

- Spark plugs.

- Muffler.

- Distribution point.

- Instruments.

- Ignition switch.

- Instruments.

- Hoses for LPG forklifts.

- Engine accessories.

- Fuel filter.

5. General

The following are general components that also need checking:

- Steering

- Brake adjustment

- Parking brake

- Horn

- Nuts, bolts and cotter pins

- Lights and alarms

- Tires

- Battery water levels

Keep in mind that the environment in which you operate your forklifts will affect how much monthly maintenance is required. For instance, machines working on a rugged fish pier will likely experience more wear than those operating in a clean pharmaceutical warehouse.

Annual Forklift Maintenance

Protocols for annual maintenance closely follow manufacturer recommendations and are generally tied to warranty protections. A yearly checkup is an opportunity for an experienced, certified technician to inspect your equipment for any repairs that will help your forklift perform optimally and extend its lifespan.

Benefits of Forklift Preventive Maintenance

Routine forklift maintenance provides the following benefits:

- Improved productivity: A forklift in top condition runs more efficiently and can move more loads, which keeps operations on schedule. Regular servicing of your forklift also reduces the chance of a breakdown, which can disrupt your business.

- Cost savings: Preventive maintenance saves on more serious, costly repairs down the line. This improves cash flow or frees up funds to spend in other parts of the business or on additional assets.

- Better safety: Preventive maintenance can prevent on-site equipment failure that puts your workers at risk and disrupts operations.

- Longer equipment lifespan: With preventive maintenance, your equipment lasts longer. You won’t have to replace the machine before the end of its expected lifespan and can save funds or grow your fleet over time.

Get Quality Used Forklifts From Chicago Industrial Equipment

At Chicago Industrial Equipment, we’ve been leaders in the forklift and aerial industry for the past four decades. We provide high-quality machines at extremely competitive prices and sell and rent a wide variety of equipment, including forklifts and dependable boom lifts. Our machines are stocked in our 50,000-square-foot showrooms or our 10-acre yard, which makes us the Midwest’s biggest forklift and aerial lift equipment dealer.

View our wide selection of quality new and used forklifts. You should have no trouble finding the perfect one for your application. If you have any questions about our products, contact us today or find a Chicago Industrial Equipment location near you.